Ever stopped to really look at a piece of welded wire mesh? It’s that unassuming grid of steel wires, fused at every single intersection, that you’ve seen a thousand times. It’s in the walls around a construction site, holding back the chaos. It’s buried deep within the concrete of the bridge you drove over this morning, silently flexing against the weight. It’s in the cage that kept that animal safely at the zoo. It’s everywhere, and it’s doing the hardest jobs without anyone ever giving it a second thought. This is the story of the silent guardian of our modern world, the unsung hero of strength and security: welded wire mesh. It’s not just a product; it’s the fundamental fabric of our built environment, the hidden skeleton that allows our grandest infrastructures to stand tall and our simplest enclosures to hold firm.

The Backbone of Modern Construction

Let’s start where it all begins: the construction site. Before the polished glass goes up or the final coat of paint is applied, there’s a phase of raw, structural honesty. This is where welded wire mesh truly shines as the indispensable backbone.

Think about a concrete slab, like the floor of a warehouse or the foundation of a home. Concrete is incredibly strong under compression—it loves to be squashed. But it’s terribly weak in tension, meaning it cracks easily when stretched or bent. That’s where our star comes in. When a sheet of welded wire mesh is placed before the concrete is poured, it becomes an integral part of the slab. As forces try to pull the concrete apart, the mesh takes up that tensile stress. The welds at every intersection are crucial here; they ensure the load is distributed evenly across the entire grid, preventing localized cracks from spreading and becoming failures. This simple act of reinforcement transforms a brittle material into a composite one that is tough, durable, and capable of handling the dynamic loads of daily life.

But it’s not just about floors. From curbs and pavements to pre-fabricated walls and tunnel linings, welded wire mesh provides a ready-made, uniformly strong reinforcement solution. Its grid structure offers excellent bond with the concrete, and its flexibility allows it to be shaped or overlapped easily. Compared to the time-consuming process of individually tying together loose rebar, rolling out sheets of mesh is a game-changer for speed, efficiency, and consistency on site. It brings a predictable and reliable strength to every part of a structure it touches.

The Guardian of Public Safety

Beyond just holding concrete together, welded wire mesh has a more visible and active role as a public safety guardian. This is where its physical presence forms a literal barrier between people and potential hazards.

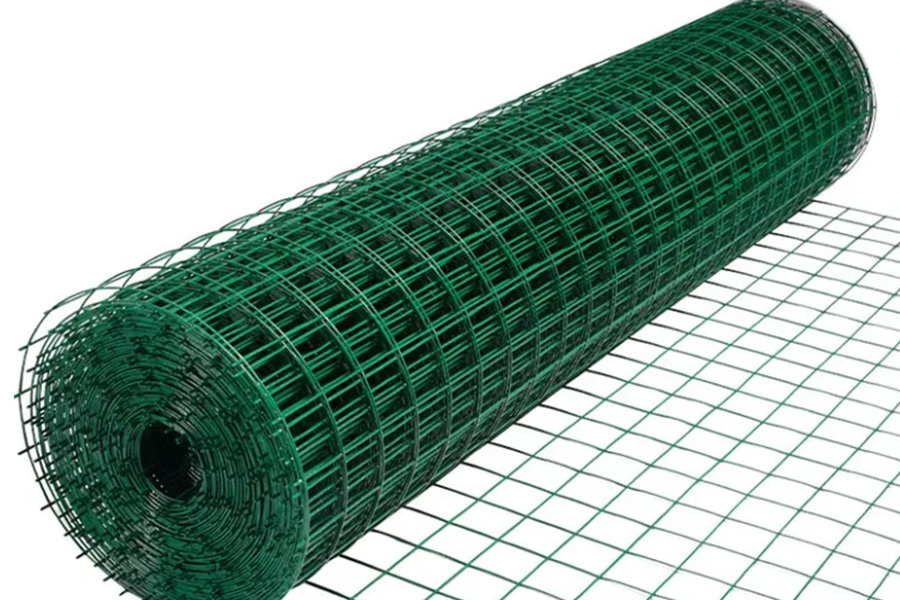

Consider highway medians and bridge parapets. The welded wire mesh used here is a heavyweight champion, designed to withstand incredible impact forces. Its job is to contain debris, prevent vehicles from crossing into oncoming traffic, or stop falls from heights. The strength comes from the quality of the steel and the integrity of the welds—each tiny fusion point must hold fast under sudden, catastrophic load. Similarly, on any construction site, temporary fencing made from welded wire mesh (often PVC-coated for visibility and weather resistance) creates a secure perimeter. It keeps unauthorized personnel out of danger zones, protects the public from falling tools or debris, and helps manage site security. It’s a versatile, see-through shield that allows work to proceed without exposing the world to its risks.

This protective function extends seamlessly into our daily environments. In public spaces like parks, schools, and sports facilities, you’ll find welded wire mesh in secure fencing and enclosures for everything from tennis courts to baseball batting cages. It provides a clear view while creating a robust boundary. For animal enclosures in zoos or kennels, specific gauges and spacings of welded wire mesh are engineered to contain different species safely and humanely, ensuring both animal welfare and visitor safety. In each of these roles, the mesh acts as a reliable, long-lasting barrier that defines safe zones and manages risk without creating an oppressive, walled-off feeling.

A Material of Surprising Versatility

Now, if you think welded wire mesh is all about brute strength in heavy construction, prepare to be surprised. Its true genius lies in its breathtaking versatility. By varying just a few basic parameters—the thickness (gauge) of the wire, the size of the grid openings, and the type of coating or finish—manufacturers can tailor this product to a seemingly endless list of tasks.

In agriculture, a lighter welded wire mesh becomes the ideal material for animal pens, poultry cages, and trellising for climbing plants. It’s sturdy, allows for air and light circulation, and protects livestock from predators. In industry, you might find heavier mesh used as machine guards, safety screens in factories, or sturdy shelving and partitions in warehouses. Its open design is key, allowing light and air to pass through while providing a solid physical barrier.

The adaptability goes even further. In residential settings, a decorative powder-coated welded wire mesh can be used for stylish garden fencing, pet enclosures, or as a supportive base for plasterwork (lath). In retail, it forms the backbone of versatile display systems and product storage solutions. From the quarry where it might be used for rock screens and grading filters to the art studio where it serves as a sculptural armature, the applications are limited only by imagination. This chameleon-like ability to serve both heavy-duty structural roles and light, functional applications is what makes welded wire mesh a staple across dozens of industries.

Engineering the Invisible Strength

What makes a simple grid of wires so reliably strong? The secret isn’t just in the steel; it’s in the weld. The process of creating welded wire mesh is a precise engineering feat that ensures consistency and performance.

Modern welded wire mesh is typically produced on automated electric resistance welding machines. Straight wires are fed at right angles into the machine. At every intersection, a powerful electrical current is passed through the wires. The resistance at the contact point generates intense heat, fusing the metals together into a solid, homogenous weld nugget. This method is fast, efficient, and creates a joint that is often as strong as or stronger than the wires themselves. The consistency of these welds across the entire sheet is critical—it’s what allows engineers to calculate the mesh’s performance characteristics with great accuracy, knowing that strength is evenly distributed.

Following welding, the mesh can undergo processes that enhance its properties. It might be galvanized—coated in a layer of zinc—to provide decades of corrosion resistance, making it perfect for outdoor and marine environments. For applications requiring both corrosion resistance and a specific color, it can be PVC-coated. For ultimate strength in reinforcement applications, it can be cold-rolled or deformed after welding, increasing its yield strength and improving its bond with concrete. This post-weld treatment is where a basic grid is transformed into a high-performance material engineered for a specific, demanding life.

The Unshakeable Future of a Classic

In an age of carbon fiber and smart materials, does a humble product like welded wire mesh have a future? The answer is a resounding yes. Its role is not diminishing; it’s evolving and cementing itself as a timeless component of resilient design.

The drive for sustainable and resilient infrastructure is actually increasing the demand for reliable, durable materials. Welded wire mesh, especially when made from recycled steel and designed for a 50-100 year service life, fits perfectly into this paradigm. It reduces maintenance needs and extends the lifespan of structures. Furthermore, innovation continues. New alloys offer better strength-to-weight ratios. Advanced coatings provide even longer protection in corrosive environments. And digital fabrication tools allow for the creation of custom-shaped mesh panels for complex architectural forms, pushing it from a purely utilitarian product into the realm of design.

From the deepest foundations to the most visible fences, welded wire mesh performs its duty silently and relentlessly. It asks for no recognition, yet it is fundamental to the safety, efficiency, and durability of our world. It is a testament to the idea that the simplest, most well-engineered solutions are often the most enduring. The next time you walk on a solid floor, drive past a secure construction site, or visit a well-kept garden, take a moment to look for that familiar grid. You’ll be looking at the essential, unbreakable fabric of modern civilization.